Not known Details About Concrete Floor

Table of ContentsGarage Floor for BeginnersAn Unbiased View of Epoxy FlooringRumored Buzz on Commercial FlooringSome Ideas on Residential Flooring You Should Know

Last upgraded March 23, 2022 Epoxy floor covering is a popular choice for industrial-grade floors. First, it's essential to know what epoxy flooring is Epoxy flooring, likewise understood as resinous flooring or polymer flooring, is a two-part combination consisting of resin as well as hardener.The chemical response produces a bond to the substrate and also forms a difficult plastic. And also, it remedies quickly so your business can get back to service swiftly. Numerous firms chose epoxy floor covering for its ease and also toughness. Epoxy flooring is the ideal solution for floors that have to withstand severe temperatures, foot and also device website traffic, chemicals, oil, as well as various other liquids without peeling off or rusting over years of constant usage.

/cdn.vox-cdn.com/uploads/chorus_image/image/68830856/1120_FEA_Idea_House_Fairfield_Farmhouse_08142020NR_0078_v3.0.jpg)

Epoxy floor covering stands up well against discolorations and also water. Unlike timber, laminate, or other sorts of flooring, epoxy does not warp or water stain as an outcome of water damage. When unpreventable spills happen, tidy up is really easy and also stains are rare. When it comes to flooring, epoxy is the most difficult! The chemical substances develop an influence resistant flooring that is perfect to handle shock, warmth, hefty machinery, and also extra without stressing over cracks and deterioration.

The 7-Minute Rule for Commercial Floor

With a smooth, glossy, and seamless look, epoxy floor covering is an attractive option for many various buildings. Epoxy floor covering provides lots of stunning shades, ideal for hotel entrance halls or athletic complicateds.

When score the flexural stamina, a lot of epoxy floors are a lot more than 3x's stronger than concrete, which is normally under 3,000 psi. Epoxy floor covering is developed to hold up against hefty machinery, high web traffic, as well as severe temperature levels such as those discovered in food handling. There is nothing stronger than epoxy floor covering! The leading top priority of any kind of firm should be security - Concrete Floor.

This is a terrific safety and security procedure for areas with high foot or machinery web traffic. Epoxy floors are also very noticeable, with no covert splits or bumps that would cause crashes. There is no threat in epoxy floor covering deteriorating or flaking to contaminate the atmosphere. Additionally, setup leaves much less waste than various other kinds of flooring.

These elements all make epoxy flooring an eco-friendly choice. Epoxy floor covering is just one of the most convenient kinds of floorings to maintain. It doesn't chip or fracture and also is impermeable as well as it will certainly last years. While there are several advantages to selecting epoxy floor covering, it is great to know all the challenges that may arise.

An Unbiased View of Flake System

Because of the seamless, smooth surface, epoxy flooring can be slippery when damp. It is recommended that you include an anti-slip finishing, which will certainly prevent falls. Conventional epoxy floorings can have a chemical smell when drying. The epoxy floor covering vapors can be dangerous if subjected to them. Nonetheless, if you give the floor correct time to treat, the off-gassing doesn't last as long as lots of kinds of flooring.

There are quicker healing epoxies than the typical 24-72 hrs so you can have a quick go back to service (http://aulavirtual.cali.edu.co/index.php/comunicacion/foro/floor-shield-of-houston-1). It is crucial to await a floor to totally heal before utilizing it. With epoxy floor covering, you will require to install a flooring underneath very first. Wood, steel, cement, or concrete can be made use of as underflooring.

Soap-based cleansers can create a cloudy staining on epoxy floorings (http://bit.do/floorshield1). To avoid this haze, utilize a cleaner especially made for epoxy floorings.

You will not need to stress over re-doing your floors, as the ordinary epoxy flooring in 2014! With ingredients, such as anti-slip and also visit this site right here anti-microbial, epoxy floorings satisfy the company needs for healthcare, manufacturing, food and also agriculture, auto, as well as lots of other markets. Below at Painters USA, we will install an epoxy flooring that is the excellent suitable for your commercial, commercial, or food processing company.

Top Guidelines Of Commercial Flooring

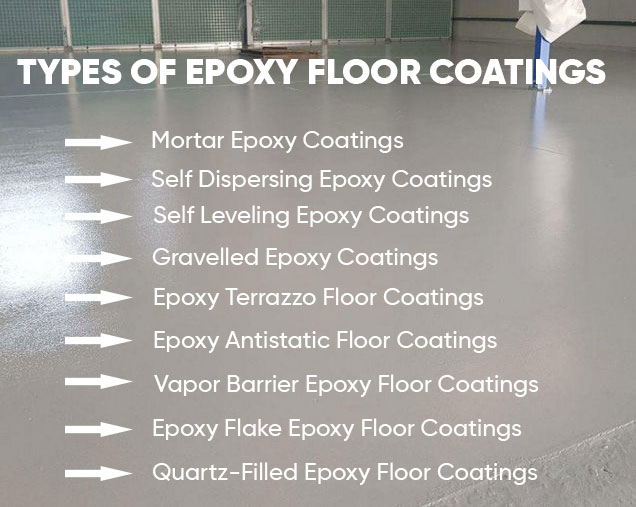

Epoxy floor layers are typically used for business and also commercial floor covering - Commercial Flooring. https://www.zupyak.com/p/3292426/t/more-about-polyaspartic-system. Epoxy coatings are generally applied over concrete floors to supply a high-performance, smooth, and resilient surface that can last years and withstand heavy lots. Lots of industrial websites, storehouses, and commercial buildings count on epoxy floors to preserve tidy and risk-free conditions for employees, equipment, as well as supply.

Epoxy might not bond to secured or brightened concrete. The concrete also must be totally cured. Before use epoxy floor finishing, it is very important to spot as well as repair all major splits and also chips in the concrete surface and to eliminate all oil. Make sure that the surface is extensively prepped and tidy prior to using the epoxy finishing.

Epoxy is a two-part fluid that you blend before application. As soon as the product is blended, you have a restricted time to apply the epoxy coating prior to it starts to set. Depending upon the item being applied, you could require to use an epoxy primer as well as finisher coat (https://www.ted.com/profiles/38488427/about). The guide is used similar to paint as well as is permitted to go for numerous hours before the epoxy takes place.